- KLINGER Australia

- Blogs

- Sealing the Deal: Sealant Tape vs Flange Gaskets Compared

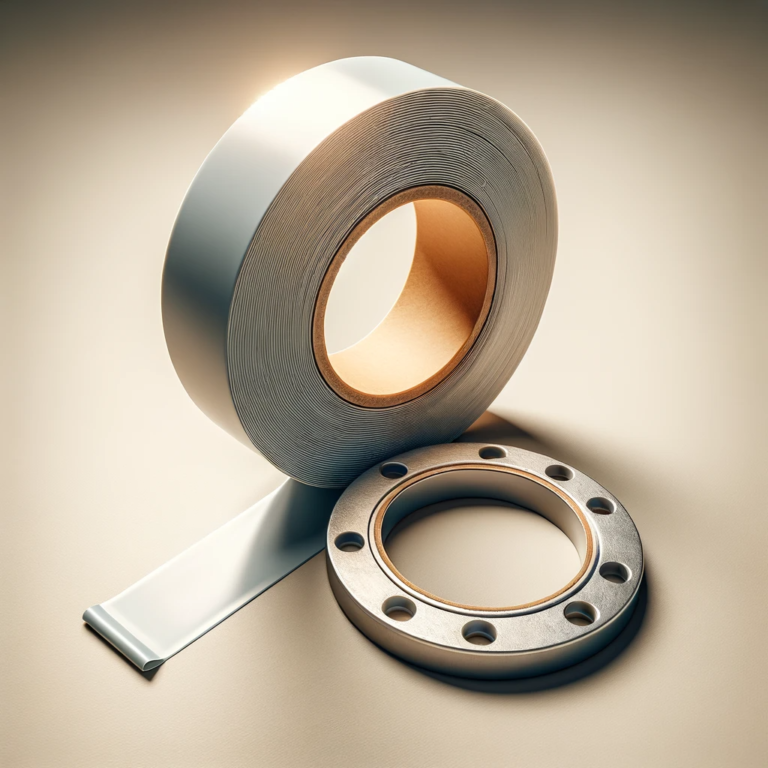

Ever wondered how you can effortlessly create a custom gasket for your unique flange shape? It’s as easy as peeling off the adhesive backing, applying it to the flange, and overlapping the ends.

The concept of using tape-like materials for sealing purposes emerged as various industries and applications demanded more versatile sealing solutions. Early forms of joint sealant tape may have been basic materials like cloth or rubber strips with adhesive applied to one side. Since its invention, the development of adhesive technologies and advancements in material science have all contributed to the evolution of joint sealant tapes. Over the years, sealant tape materials and formulations have become more specialised and tailored to specific industries and applications. Today, you can find a wide range of sealant tapes made from various materials, including silicone, rubber, foam, PTFE and more.

Key Characteristics of Joint Sealant Tape

- Adhesive Backing: Featuring an adhesive backing, the tape bonds seamlessly with various surfaces, delivering an instant, dependable seal.

- Flexibility: These tapes are exceptionally flexible and conformable, adapting seamlessly to irregular surfaces, corners, and joints, ensuring a secure and uniform seal.

- Ease of Installation: Installation is a breeze, requiring no complex equipment or extensive training. Simply cut it to size and apply it directly to the joint or surface.

Great for Complex Flanges and Equipment

Joint sealant tape shines when it comes to complex flanges and equipment, where traditional gaskets or liquid sealants may face challenges. It excels in sealing steel flanges with large diameters, irregular shapes, or rough/pitted surfaces. When compressed, it forms a thin yet robust seal and performs admirably in applications with low bolt loads.

Sealant Tape and Flange Gaskets

A Side by Side Comparison

While sealant tape is celebrated for its ease of application and flexibility, standard flange gaskets are renowned for their robustness and precision in high-pressure environments. By delving into the specifics of each product, from material composition to application versatility, we will unravel the truth behind their efficacy and suitability.

Which product is more durable

Flange gaskets are fashioned from materials chosen for their durability and resistance to chemicals and environmental factors. Their lifespan, however, depends on the material and operating conditions. Sealant Tape in comparison, may degrade faster under high temperatures or pressures. Its longevity can also be affected by chemical exposure or environmental conditions.

Winner: tie

Which product provides more physical and application flexibility

While some flange gasket materials, such as rubber or certain flexible composites, do offer a degree of flexibility, they generally do not match the level of physical pliability found in sealant tapes. Made from materials like PTFE, silicone, or rubber, sealant tape can easily conform to various shapes and surface irregularities. This makes it highly adaptable for sealing a variety of joint types.

Winner: Sealant tape

Which one performs better under pressure and has better temperature resistance

Flange gaskets are engineered to excel in high-pressure, high-temperature industrial environments, offering enduring seals where extreme conditions prevail. Depending on the materials, some sealant tape can do quite well under such strenuous conditions.

Winner: gasket.

Which one is easier for installation and maintenance

flange gaskets generally require more precise installation and maintenance, and gasket replacement can be more labor-intensive. Sealant tape is easier to apply and maintain but might require more frequent checks in demanding applications due to potential degradation.

Winner: tie

Material Choices

Flange gaskets offer a wider variety of materials, including rubber (neoprene, nitrile, EPDM), non-asbestos composites, flexible graphite, PTFE, silicone, metal (stainless steel, copper), and specialised materials like Viton and Kalrez. The greater variety in materials for flange gaskets is driven by the need to match the gasket material with the specific mechanical, thermal, and chemical requirements of the joint or system they are sealing. Sealant Tape are typically made from fewer types of materials including PTFE, butyl, silicone, and synthetic rubbers.

Winner: Gasket.

Flange gaskets excel in providing uniformity and precision, and conforming to exact dimensions that ensure consistent and reliable sealing. This level of uniform and precision is more challenging to achieve with sealant tape, especially in critical applications where the slightest deviation can compromise safety. Because of this, they are frequently the preferred choice in many safety-critical industrial applications. However, it’s crucial to note that the choice between gaskets and sealant tape depends on the specific needs of the application. Sealant tape remains a fantastic choice in situations where flexibility, adaptability, or cost-effectiveness take precedence over other factors. The key lies in understanding the nuances and selecting the solution that aligns with your unique sealing challenge.

Sealex® joint sealant

Ideal for challenging applications like glass-lined steel equipment or high-temperature environments, alternating pressures, low gasket loads, or deviations in surfaces.

- Specially processed, 100% pure PTFE on a roll.

- Offers soft, highly compressible gasketing for extended durability.

- Versatile form-in-place application reduces maintenance and storage expenses.

- High compressibility effectively fills flange imperfections, ensuring a tight seal.

If you require a gasket that merges the robustness and reliability of traditional gaskets with flexibility, you might want to consider exploring ePFTE gaskets. These products are designed to offer the best of both worlds: the strength and durability needed for demanding applications, along with the adaptability features akin to sealant tape. They are highly flexible, which allows them to conform easily to various surface irregularities and shapes, making them a great option to consider for applications where surface irregularities might be an issue.

KLINGER Softchem Gaskets

High compressibility allows it to adapt to irregular flange faces, ensuring a secure seal with minimal stress.

- Crafted from 100% expanded PTFE without binders, fillers, or additives.

- Its unique construction minimises creep and cold flow, offering exceptional durability.

- While it conforms to rough sealing surfaces with ease, it compresses into a robust gasket, forming a tight, enduring seal.

- Thanks to a proprietary manufacturing process, it maintains uniformity and a highly fibrillated microstructure with equal tensile strength in all directions.

- Plus, its remarkable memory characteristics eliminate the need for retorquing bolts.

Whether you’re tilting towards gaskets for its reliability or leaning towards sealant tape for its user-friendliness, we know there’s more you’d love to uncover. Hit the ‘Contact Us’ button below to get personalised advice, insider insights, and answers to all your questions.