- KLINGER Australia

- Products

- Jointing / Gasket Materials

- Compressed Fibre

- KLINGERSIL® C-4243

Products

Need help with a product?

Get in touch

Call 1300 798 279 (from Australia)

+61 8 9251 1688 (outside Australia)

OR send us your enquiry

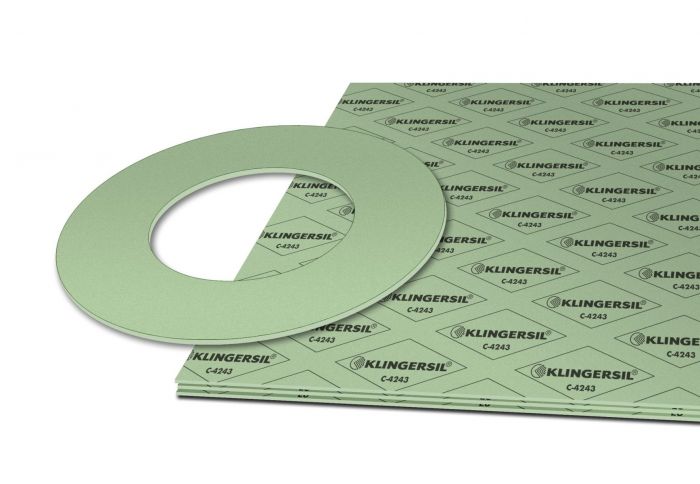

KLINGERSIL® C-4243

Universal gasket material for general industrial applications.

Gasket material for liquids and gases at lower pressure and temperatures.

Basis

Aramid fibres bonded with NBR.

Areas of application

Resistant to water and oil.

Typical technical data for thickness 2.0 mm

%

8

%

55

50 MPa,16 h / 175 °C

MPa

24

50 MPa

thickness decrease at 23 °C

thickness decrease at 300 °C

%

%

10

25

DIN 3535/6

mg/s x m

0.1

oil IRM 903: 5 h / 150 °C

fuel B: 5 h / 20 °C

%

%

5

7

g/cm³

1.75

Dimensions of the standard sheets

Sizes

1000 x 1500 mm, 2000 x 1500 mm

Thicknesses

0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm, 3.0 mm

Tolerances

Thickness acc. to DIN 28091-1

Length ±50 mm, Width ±50 mm

Other sizes, thicknesses and tolerances on request.

Function & Durability

The performance and service life of KLINGER gaskets depend in large measure on proper storage and fitting, factors beyond the manufacture’s control. We can, however, vouch for the excellent quality of our products. With this in mind, please also observe our installation instructions.

Downloads

Below you can find more product-related Information.

View Related Products

KLINGERSIL® C-4408

KLINGERSIL® C-4409

KLINGERSIL® C-4430

KLINGERSIL® C-4430PLUS