- KLINGER Australia

- Blogs

- Behind the Counter: Fast Gasket Replacement at KLINGER Gladstone

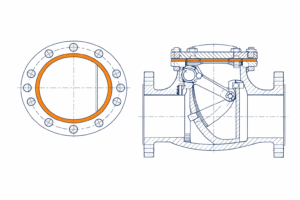

When a customer walks into our Gladstone branch with a damaged gasket, it usually means one thing: they have equipment offline, time is critical, and they need a replacement fast. Every hour of downtime can cost thousands or more, so the pressure to get it right, and get it done quickly, is real.

That’s where being based in Gladstone makes a difference. This isn’t a big city with long supply chains and delays. Our office is right here, close to our customers’ sites, which means they can walk in, hand over the damaged part, and start the process immediately. With a warehouse on site and the capability to cut gaskets locally, we can move straight from counter conversation to production.

At the counter, one of the friendly faces you’ll see is Amanda. She’s the one who begins the conversation, making sure the essentials are clear before the gasket moves further down the line.

Step 1: Asking the Right Questions

“The first few minutes are all about questions,” Amanda explains. What material is this? How thick? How many are needed, and how soon?

If it’s a gasket we’ve supplied before, it’s straightforward. If not, the customer describes the application pressure, temperature and medium so the team can recommend the right alternative. At the same time, stock levels are checked, and the warehouse is notified.

- Material –Identified directly if it’s ours or chosen based on the application pressure, temperature and medium.

- Dimensions and Thickness – Checked against the damaged gasket and confirmed with the warehouse.

- Quantities – Whether it’s one or many can affect turnaround.

- Urgency – Most walk-ins need the gasket by the same day or next morning.

Step 2: Checking Stock and Feasibility

With the details in hand, Amanda confirms whether the right sheeting material is available and whether the job can be cut in Gladstone. Our local stock holdings include a broad range of compressed fibre, rubber, graphite, and PTFE sheets, which mean we can usually move straight to production without delay.

Step 3: From Gasket to Waterjet

The damaged gasket is turned into a DXF drawing for the waterjet cutter. If there’s uncertainty, the team may do a trial cut on scrap material to test against the original before committing. Once confirmed, the final gasket is cut, usually the same day or first thing the next morning, depending on other urgent jobs.

Step 4: Ready for Collection

When the gasket is complete and paperwork cleared, the customer gets the call. For crews under shutdown pressure, that moment often makes the difference between extended downtime and being back in action.

Amanda says: “We’ve done this process countless times, and every situation is different. But the one thing that’s the same is how important speed and accuracy are for our customers.”

From the customer’s view, the process looks simple: hand over a gasket, collect a replacement. But behind the counter, it’s a sequence of quick decisions, technical checks, and teamwork across customer service, warehouse, and sales. As Amanda puts it: “People often see just the handover, but there’s a whole team moving quickly behind the scenes. Our job is to make sure that by the time the customer walks back out, they know the problem is already being solved.”

Gladstone is one of KLINGER Australia’s stocking and manufacturing branches, giving customers direct access to both product and local production capacity. Together with our facilities in Welshpool (Western Australia) and Rayong (Thailand), it forms part of a regional network designed to reduce lead times, cut transport costs and keep our customers’ operations moving.

Share this article on social

Need help with a product?

Get in touch

Call 1300 798 279 (from Australia)

+61 8 9251 1688 (outside Australia)

OR send us your enquiry