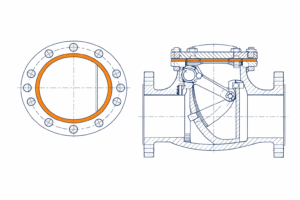

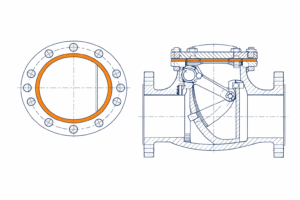

The Geometry That Led the Sealing Engineering Work

A case study in sealing engineering showing how valve geometry, compression windows and local manufacturing enabled a reliable 21 MPa feedwater solution.

A case study in sealing engineering showing how valve geometry, compression windows and local manufacturing enabled a reliable 21 MPa feedwater solution.

Discover how KLINGER Australia’s Gladstone branch turns a damaged gasket into a new one—fast. With local stock, onsite waterjet cutting, and a skilled team, we help customers minimise downtime and keep operations moving.

Marking 30 years of service at KLINGER Australia, we celebrate the quiet dedication and steady contribution of a team member whose work has helped shape our gasket production from the factory floor to the lab.

Explore how Flame Ionisation Detection (FID) works, its strengths, limitations, and how it integrates with QOGI and Hi-Flow for effective emissions monitoring.

Discover the key differences between expansion joints and flexible hoses, and learn why using the right component for the right application is critical to preventing system failures.

This International Women’s Day, we celebrate strong women in our business. See how Jodie, our Internal Sales Manager sees leadership, and makes an impact.

KLINGER Australia delivered oversized gaskets specifically engineered for a large hydrogen cylinder, tackling the unique challenges of both manufacturing and transportation with smart solutions.

KLINGER Thailand is thrilled to announce its recognition as the only Platinum Award recipient at PTTEP’s 2024 Supplier Performance Excellence Awards.

With the new GlobalMAX 2040 waterjet cutter, our workshop now offers precise, versatile cutting for metals, plastics, and composites.

We are currently away celebrating the holidays with our families and friends. Thank you for your understanding, and we look forward to serving you in 2025.