- KLINGER Australia

- Blogs

- The Geometry That Led the Sealing Engineering Work

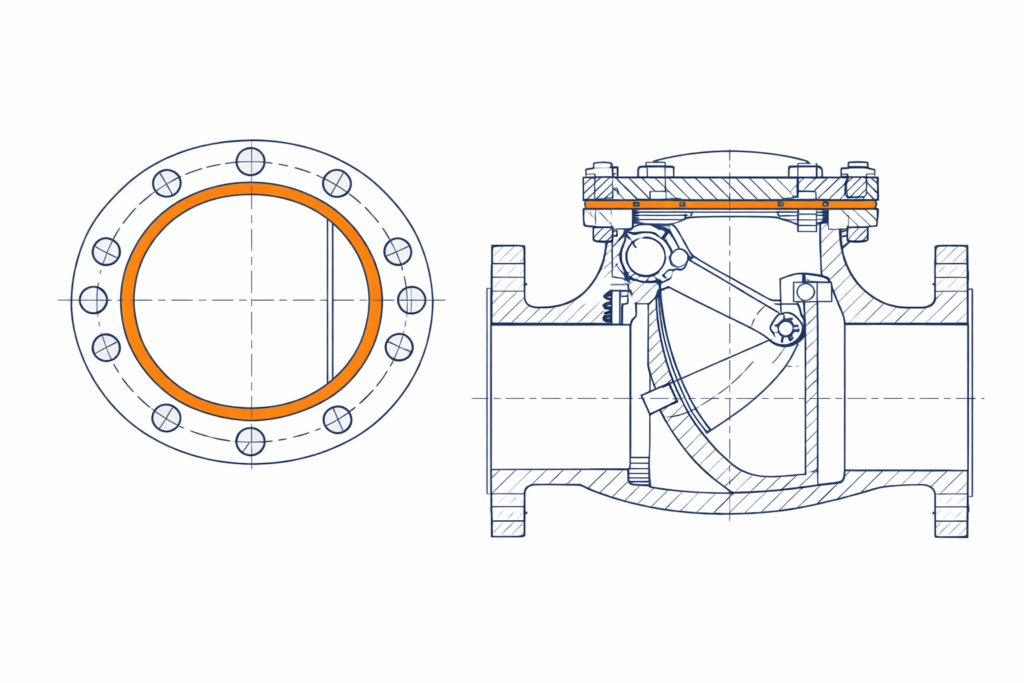

It began with a feedwater valve on a 6 MW electric pump, a piece of equipment that had operated reliably for years. During a planned overhaul, the outage team removed the OEM sealing ring, and paused. Inside the valve body was a narrow, finely machined groove: the type of geometry seen on older or proprietary equipment, designed around a specific ring made at the time of manufacture. This raised a question: Could this space accept a new, locally manufactured sealing solution that would operate reliably at 21 MPa?

That question set the stage for a smart and highly collaborative piece of engineering work.

A Geometry that Asked for Thought

The OEM groove provided a perfectly machined space but clearly optimised for its original proprietary ring.

- ≈2.94 mm radial width

- ≈1.8–2.0 mm axial depth

- Compressed height window: 2.85–4.47 mm

This is common in legacy equipment. Geometries are tightly matched to the OEM component they were designed for.

The client’s engineer provided photos, dimensions and verified the internal clearances. Using this information, KLINGER assessed whether modern gasket options could reliably operate in the OEM location:

- Modern Kammprofiles require more radial land than the groove provides.

- Graphite laminates fit physically, but offer limited stability in high-pressure, high-torque service.

Rather than forcing a compromise, the client’s engineering team proposed evaluating an alternative seating surface inside the valve. This surface provided significantly more radial width along with a stable axial surface. They also confirmed the hinge pin housings could be remanufactured in 431 stainless steel if required to maintain float tolerances.

KLINGER validated the geometry, compression behaviour and torque requirements. With both teams aligned, more technically robust gasket options became viable.

The Gasket That Fits the Sealing Need

With the alternative seating surface confirmed suitable, the preferred option was clear:

Kammprofile T109 LA2, 316L Stainless Steel with Graphite, 65.0 × 45.5 × 4.0 mm

Kammprofiles’s metal-supported stability with controlled compression, making them ideal for high-pressure feedwater service. The wider seating surface allowed safe torque application without risk of over-compression. This configuration provided:

- a stable metallic core

- predictable compression into the tolerance window

- secure seating on the wider land

- appropriate torque capacity for high-pressure feedwater service

- manufacturability within the outage timeframe

A Confident, Local Solution

One key advantage stood out throughout the project: KLINGER’s engineering department and manufacturing capability are fully onshore. Teams based in Queensland and Perth worked closely with the client’s engineers to assess constraints, evaluate options and converge on a solution that respected both the valve geometry and the outage schedule. Once agreed, KLINGER’s local manufacturing capability meant the gasket could be produced right here in Australia.

This combination, local engineering + local manufacturing, turned a complex sealing challenge into a fast, confident technically grounded outcome within days.

No offshore delays.

No slow communication loops.

No long international lead times.

We reviewed the measurements, constraints and technical considerations together as we compared the available options. With our engineering support and the ability to manufacture urgently here in Australia, we delivered a solution that fit both the valve design and its service demands. I’m very proud to have contributed to such a strong outcome.”

Sam Patel, Sales Representative QLD and KLINGER’s point of contact for the project, shared his perspective.

The Strength Behind the Outcome

“I want to personally thank each of you (KLINGER) for your tremendous support and massive effort the past week, to manufacture and deliver these gaskets on such short notice. I was highly impressed by each of you and the wider KLINGER team, to innovate and adapt to our gasketing demands and provide multiple engineered solutions.”

Client feedback reflected the success of this collaborative approach.

While we are proud of what our team delivered, we believe the success was also shaped by the way the problem was approached. In this case, the client’s team provided:

- Clear photos and precise measurements

- Verified tolerances around the disk, bushings and hinge housing

- Practical, forward-focused questions

- Openness to evaluating alternative sealing locations

This clarity enabled KLINGER to assess every possibility with engineering discipline:

- Could the OEM groove safely support a metallic profile?

- What torque window would work reliably?

- What radial seating width was required for stability?

- Was another sealing location inside the casting more suitable?

Sealing Engineering Principles That Guided the Work

Several core sealing-engineering principles proved essential:

- Base decisions on verified dimensions, not assumptions.

- Assess whether the original OEM design intent still fits today’s requirements.

- Let geometry and service conditions guide the design.

- Ensure every solution reflects real constraints, not convenience.

Most importantly, effective engineering is never done in isolation. The strongest outcomes come from clear communication, shared understanding, and a willingness to explore the right options together.