Find and reduce Methane emissions leaks

In recent years, many power companies have transitioned from using coal to natural gas as their primary source of energy. This shift was motivated by concerns over the negative environmental impacts of coal, which is one of the most carbon-intensive fossil fuels. While natural gas also produces carbon dioxide when burned, it is considered to be a cleaner source of energy due to its lower carbon emissions compared to coal.

However, the transition to natural gas is not without its own environmental challenges. In particular, scientists from the National Oceanic and Atmospheric Administration (NOAA) have observed a worrying trend in recent years – a significant increase in atmospheric levels of methane, a primary component of natural gas.

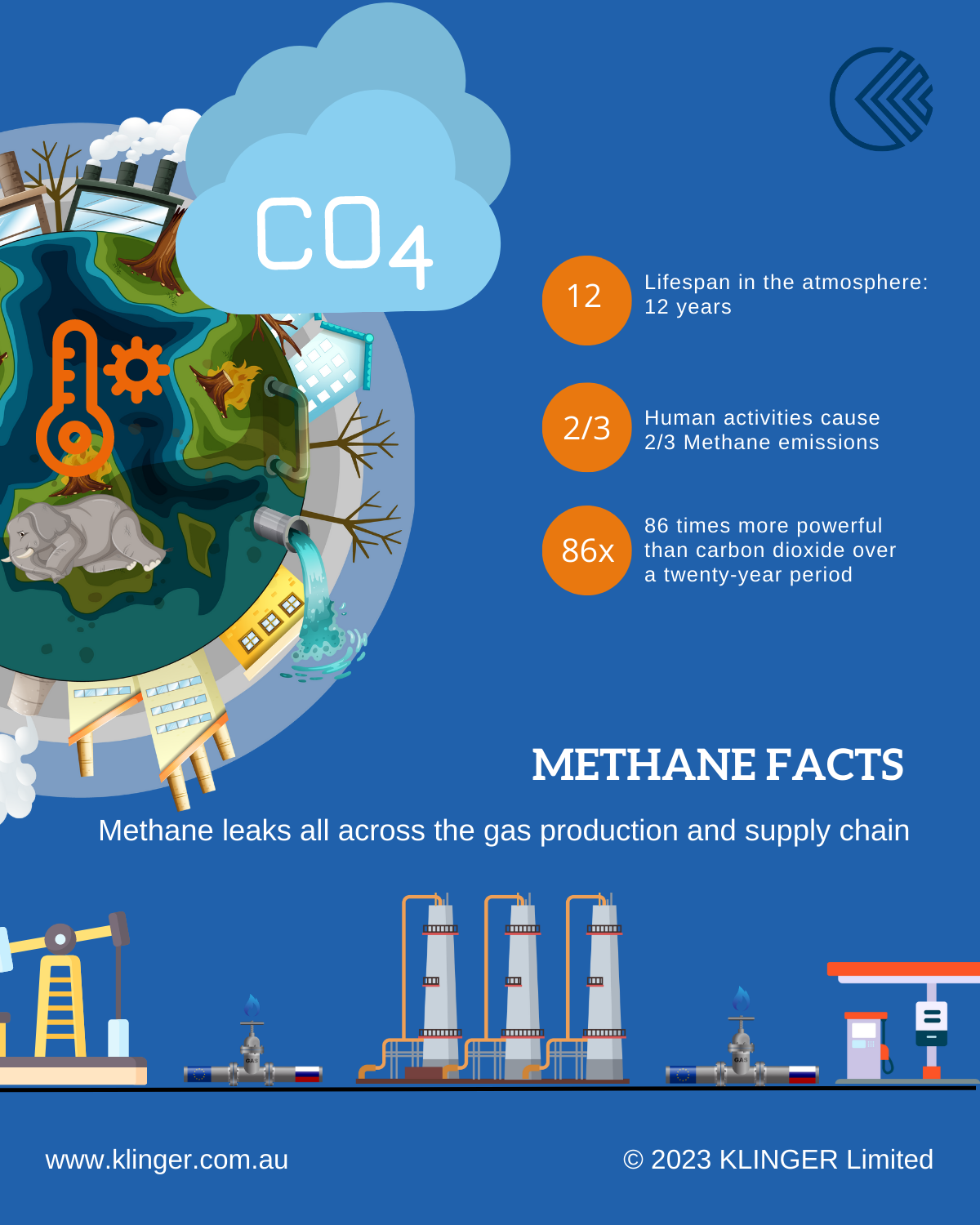

Although methane releases only about half the emissions of coal when combusted, it has a much higher global warming potential than carbon dioxide over a 20-year period when released into the atmosphere. According to the United States Environmental Protection Agency, Methane currently accounts for approximately 16% of total GHG (greenhouse gases) emissions and contributes to 30% of the heat trapped by all GHG. Recent technological advancements and research findings have further revealed that methane emissions have likely been underestimated, and reducing methane emissions is a crucial goal that should be a priority for everyone and strategies to achieve this must be given due importance.

One of the reasons why reducing methane emissions is so crucial is that methane typically persists in the atmosphere for about 12 years, compared to hundreds or even thousands of years for carbon dioxide. Hence, reducing methane emissions can have a more immediate impact on slowing down the advancement of climate change.

Efforts to reduce methane emissions are gaining momentum

Natural gas is commonly extracted from underground reservoirs using drilling wells. After extraction and then transported through pipelines and stored in tanks before it is distributed to consumers. During this process, methane can escape from equipment leaks, pipeline venting and incomplete combustion. According to the International Energy Agency (IEA), oil and gas operations are the largest source of methane emissions from the energy sector.

The release of methane into the atmosphere not only has significant environmental consequences. Methane emissions also represent a waste of natural resources, as they reduce the amount of natural gas available for use. In the US alone, the annual value of lost methane due to such leaks is estimated to be $2 billion, sufficient to power 10 million homes for an entire year.

Many oil and gas companies are adopting measures to reduce emissions, such as leak detection and repair programs. Governments are also taking action to regulate methane emissions, including setting emissions standards and requiring regular monitoring and reporting of emissions.

A holistic approach towards methane emissions leaks

Although significant gas leaks in oil and gas infrastructure are typically dealt with promptly, smaller leaks may go unnoticed for extended periods. These leaks can be a result of equipment malfunctions, corrosion, or wear and tear, and can occur at any point in the production and distribution process.

The lack of odour and colour in methane makes it difficult for operators to detect small leaks by visual inspections alone. Methane detection tools like point source gas analyzers, infrared cameras, acoustic leak detectors, ultrasonic flow meters, drones, and satellites can be used to detect methane leaks that are not visible to the naked eye and installed at key points in the infrastructure, allowing for continuous monitoring and alerting operators to the presence of leaks.

Once leaks are identified, a majority of them can be fixed quickly by sealing connections or replacing worn-out seals. In addition to repairing work, companies are also taking proactive measures to reduce the occurrence of leaks in the first place. This includes implementing regular inspections, using advanced leak detection technologies, and improving maintenance practices to ensure that equipment remains in good working order.

The Challenge of implementing LDAR type programs for reducing methane emissions

Implementing Leak Detection and Repair (LDAR) type programs is an essential step in reducing methane emissions from oil and gas infrastructure. However, it can be a challenging and intricate task that requires specialised knowledge, practical experience, and a thorough understanding of regulatory requirements. Each situation is unique and requires a customised strategy to ensure that the LDAR program is effective and compliant.

- One of the primary challenges in implementing LDAR programs is identifying potential sources of leaks. This can be particularly challenging in large and complex facilities, where there may be numerous points of potential leakage. Leak detection technologies, such as infrared cameras and sensors, can be effective in identifying leaks, but they require skilled operators to interpret the results and make informed decisions.

- Even small leaks can have a significant impact on emissions over time, so it is essential to have a process in place for quickly identifying and repairing leaks. This requires regular monitoring and maintenance of equipment, as well as a culture of continuous improvement in which the goal is to minimise emissions wherever possible.

- The rules and regulations governing methane emissions can be complex and vary from one jurisdiction to another. Staying up to date with regulatory changes and ensuring compliance with these requirements is essential to avoid fines and penalties.

- Implementing LDAR programs requires companies to allocate resources for equipment, personnel and training. While the benefits of reducing methane emissions from leaks are significant, companies must carefully balance the costs and benefits of implementing these programs to ensure that they are financially sustainable.

To ensure the effectiveness of the program, it is important to work with a supplier who is experienced in developing an LDAR program that meets the unique operational needs of the customer, offers advanced technologies and equipment, and understands the complex landscape of regulations and standards related to methane emissions.

About KLINGER

KLINGER is a leading provider of leak detection and repair and emission monitoring. With over 25 years of experience in the industry, KLINGER has developed a deep understanding of the challenges associated with methane emissions, and is committed to providing comprehensive solutions that address these challenges.

Comprehensive Leak Detection

KLINGER’s comprehensive leak detection services monitor all reportable assets, speciate each asset process for reporting on methane contributors. We incorporate the latest technologies quantitative gas imaging cameras QOGI (quantitative optical gas imaging), high flow sampling and bagging options in our services for accurate leak detections even in hard-to-reach areas.

Data Management and Reporting

KLINGER uses an internally developed CIMS® component integrity management database to identify and characterise pipeline components, record their integrity performance and any actions recommended to provide clients with valuable insights into their system health and opportunities for fugitive gas reduction.

Proactive Maintenance

KLINGER’s maintenance programs can prevent methane leaks before they occur.

Compliance Support

KLINGER provides compliance support to help clients meet regulatory requirements.

Ongoing Support

KLINGER helps clients maintain their leak detection and repair programs over the long term, ensuring continued GHG emission reduction.

There is no one size fits all solution for methane leak control and reduction. It requires a combination of innovative technologies, collaborative efforts among stakeholders, and a culture of continuous improvement in which the goal is to minimise emissions wherever possible.

Silvio Stojic, General Manager, KLINGER ATMECO