- KLINGER Australia

- Products

- Jointing / Gasket Materials

- Compressed Fibre

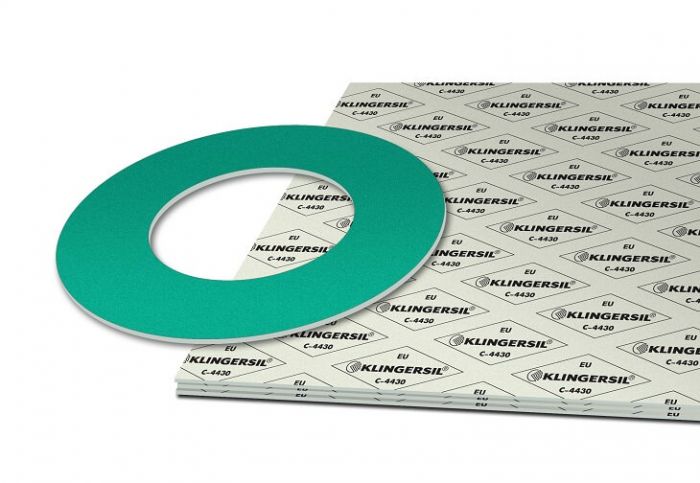

- KLINGERSIL® C-4430

Products

Need help with a product?

Get in touch

Call 1300 798 279 (from Australia)

+61 8 9251 1688 (outside Australia)

OR send us your enquiry

KLINGERSIL® C-4430

Outstanding stress relaxation and resistance to hot water and steam.

KLINGERSIL® C-4430 gasket offers outstanding stress retention and resistance to hot water and steam.

Basis

Optimum combination of synthetic fibre, bonded with NBR.

Areas of application

Resistant to water and steam at higher temperatures as well as to oils, gases, salt solutions, fuels, alcohols, moderate organic and inorganic acids, hydrocarbons, lubricants and refrigerants.

Key features

- Optimum combination of synthetic and glass fibres

- Outstanding stress relaxation

- Dimensionally stable

Benefits

- Suitable for high temperature steam and water

- Better resistance against hydrocarbons

- Suitable for many different media

CERTIFICATES & APPROVALS

- BAM-tested

- DIN-DVGW

- DIN-DVGW W 270

- DVGW VP 401

- Elastomer-Guideline

- WRAS approval

- German Lloyd

- TA-Luft (Clean air)

- Fire-Safe acc. to DIN EN ISO 10497

- Fire-Safe acc. to ISO 19921

Typical technical data for thickness 2.0 mm

%

9

%

55

50 MPa,16 h / 175 °C

50 MPa,16 h / 300 °C

MPa

MPa

39

35

40 MPa,16 h / 300 °C

MPa

31

50 MPa

thickness decrease at 23 °C

thickness decrease at 300 °C

%

%

8

11

DIN 28090-2

mg/s x m

0.05

VDI 2440

mbar x l/s x m

2.13E-05

immersion ASTM F 146

oil IRM 903: 5 h / 150 °C

fuel B: 5 h / 23 °C

%

%

3

5

g/cm³

1.8

pO

Ω

4.1x10E13

pD

Ω cm

4.5x10E12

Ed

kV/mm

21.3

50Hz

tan δ

0.03

50 Hz

εr

6.7

λ

W/mK

0.38

Grade AX

ASME-Code sealing factors

tightness class 0.1 mg / s x m

MPa

y 20

m 1.1

tightness class 0.1 mg / s x m

MPa

y 20

m 1.6

tightness class 0.1 mg / s x m

MPa

y 20

m 2.2

Dimensions of the standard sheets

Sizes

1000 x 1500 mm, 2000 x 1500 mm

Thicknesses

0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm, 3.0 mm

Tolerances

Thickness acc. to DIN 28091-1

Length ±50 mm, Width ±50 mm

Other sizes, thicknesses and tolerances on request.

Function & Durability

The performance and service life of KLINGERSIL® C-4430 gaskets depend to a large extent on proper storage and fitting – factors beyond the manufacture’s control. We can, however, vouch for the excellent quality of our products. With this in mind, please also take note of our installation manual.

Downloads

Below you can find more product-related Information for KLINGERSIL® C-4430 gaskets.